High-tension board three-in-one feeder is the future development trend

2020-06-23(1605)Views

Stamping forming is an important forming method in modern manufacturing industry, which is widely used in industries such as cars, aerospace and shipbuilding. Then in the stamping process, there are many technical problems, and the data of many high-tension plates will rebound after passing through the leveling roller. It not only affects the dimensional accuracy of the parts, but also brings many inconveniences for the subsequent installation.

According to China's energy-saving and new-energy car skills roadmap, it is required that in 2020, 2025, and 2030, the whole vehicle will be reduced by 10%, 20%, and 35% compared to 2015. By 2030, the proportion of high-strength steel applications will increase significantly, and aluminum for bicycles The amount exceeds 350Kg, the magnesium alloy for bicycles is 45Kg, and the use of carbon fiber accounts for 5% of the vehicle weight. Lightweight body is also an important skill path for energy saving and consumption reduction, focusing on the investment opportunities brought by the increase in the consumption of aluminum alloys, magnesium alloys and carbon fiber bicycles.

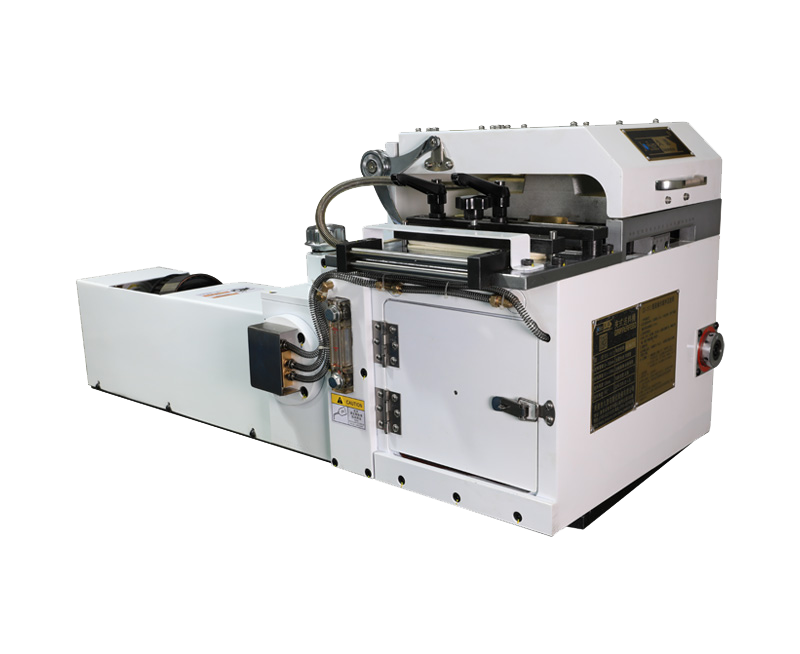

With the development of lightweight cars, the application of high-tension plate materials has been rising and falling. For the machinery industry, it is a certain trend to develop machines that adapt to high-tension plate materials. At the beginning of this year, our company received an order for a 1.3-meter large three-in-one feeder with a high-tension plate from Harbin FAW supplier. It is equipped with a 1250-ton large punch press. The data is DP780 and is attributed to the high-tension plate. Our company has discussed before the high-tension board, so it is specially planned on this machine, a total of 9 leveling rollers on the upper 5/lower 4 and 3 sets of back pressure rollers on the upper and lower sides, and the servo motor is increased. Driven by a reducer, the commissioning is now complete and the leveling effect is surprisingly good.

In recent years, the trend of "lightweight" cars has become more and more obvious, and more and more new materials are used, such as high-strength steel, aluminum alloys, magnesium alloys, etc., some light alloys, and high-strength steels are the most important in the stamping process The outstanding problem is the big rebound.

Recommended News

-

What are the classification and advantages of the three-in-one feeder?

The three-in-one feeder is a highly efficient feeding equipm...

-

High-tension board three-in-one feeder is the future development trend

Stamping forming is an important forming method in modern ma...

-

Selection of high-speed roller feeder

The high-speed roller feeder is the most widely used feeder ...

-

Clip feeder-the preferred feeder for high-speed punches

The high-speed punching machine is the most commonly used pr...

Contact Us

Service Hotline+86 13580817073

—— WeChat communication

+86 13580817073

+86 13580817073